Designing with Precision: Custom Polycarbonate Sheets for Unique Box Creations

The Art of Crafting Custom Polycarbonate Sheet Boxes

Polycarbonate sheets have become a popular choice for designers and manufacturers due to their unique properties such as durability, transparency, and flexibility. These sheets are ideal for creating custom boxes that not only protect but also enhance the aesthetic appeal of the items inside. The precision required in manufacturing these custom polycarbonate sheet boxes is crucial to ensure they meet both functional and design standards.

The Precision Required in Manufacturing

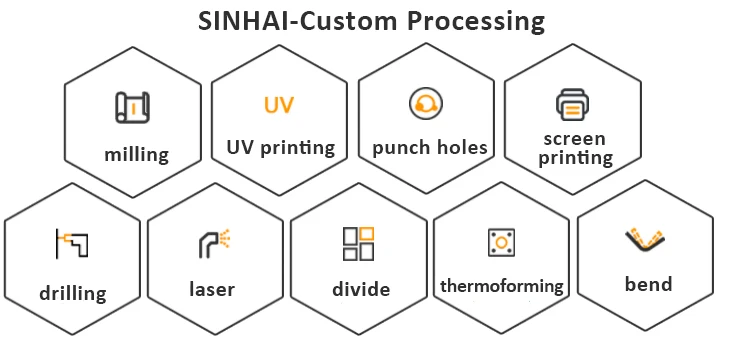

The process of designing and crafting custom polycarbonate sheet boxes begins with careful planning and precise measurements. Each sheet must be cut to exact specifications using advanced CNC (Computer Numerical Control) machines, which allow for intricate cuts and bends without compromising on strength or aesthetics. The material’s ability to withstand high temperatures during forming processes makes it possible to create complex shapes and designs, adding an element of creativity to the manufacturing process.

Moreover, the use of specialized tools and techniques ensures that each box maintains its structural integrity even under extreme conditions. This level of precision is vital for applications where the box must protect delicate contents from impact, temperature fluctuations, or other environmental factors. Manufacturers must adhere to stringent quality control measures at every stage of production to guarantee that the final product meets the highest standards of craftsmanship.

Creative Freedom for Designers

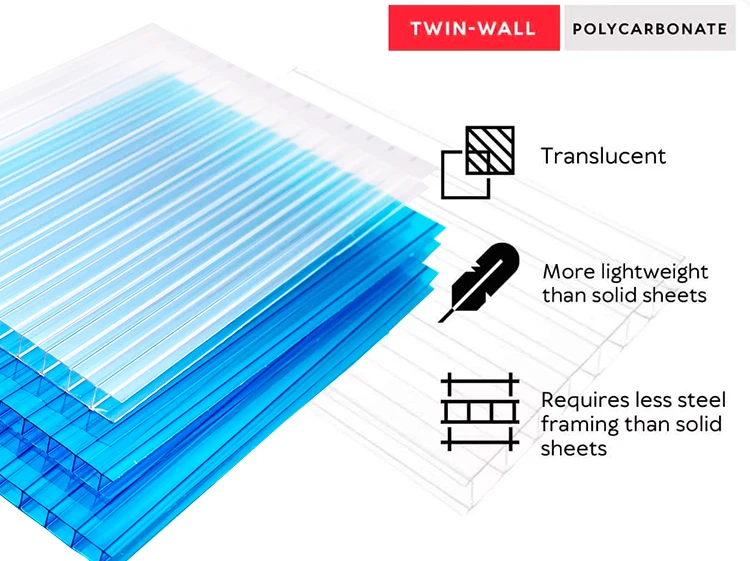

While precision is key in the manufacturing process, custom polycarbonate sheet boxes also offer designers unparalleled creative freedom. Unlike traditional materials like wood or metal, polycarbonate allows for greater flexibility in design. Its semi-transparent nature can be manipulated to create visually striking effects, making it perfect for luxury packaging or display cases. Designers can experiment with various colors, finishes, and textures to achieve the desired look and feel for their projects.

Additionally, the lightweight yet robust nature of polycarbonate sheets makes them suitable for a wide range of applications, from consumer electronics packaging to architectural elements. This versatility enables designers to think outside the box and push the boundaries of conventional design approaches. Whether it’s a sleek, modern look or a more organic, artistic design, polycarbonate sheets provide the perfect canvas for innovation.

Conclusion

Custom polycarbonate sheet boxes represent a perfect blend of precision engineering and artistic expression. The meticulous attention to detail in their manufacture ensures that these boxes are not just functional but also visually appealing. At the same time, the creative possibilities offered by this material empower designers to bring their visions to life in ways previously unimaginable. As technology continues to advance, we can expect even more innovative uses of polycarbonate sheets in the future, further revolutionizing the world of custom packaging and design.

Reference

The Advantages of Polycarbonate Sheets

- Durable and Long-Lasting: Our Transparent Support Clear Polycarbonate Smoked Multiwall Twinwall Plastic Roof Sheet Hollow Greenhouse Panels offer a 10-year guarantee, ensuring that your investment lasts for years to come, providing peace of mind for our valued customer.

- Customizable Options: We cater to diverse needs by offering various thicknesses (3mm-20mm), widths (1220mm and 2100mm), and colors (clear, green, blue, brown, and opal) to match your specific requirements, including customized solutions as requested by the customer.

- Multi-Functional: Our product is suitable for various applications such as greenhouse skylights, carports, awnings, and roofing, allowing you to utilize a single product for multiple purposes and projects, including golf training aids in sports and entertainment.

- Advanced Features: Our polycarbonate sheet boasts impressive features such as anti-aging, thermal insulation, impact resistance, and fire resistance, ensuring a safe and efficient use of the product in various settings.

- Comprehensive After-Sales Support: We provide online technical support, onsite installation, onsite training, and installation instructions to guarantee a seamless and hassle-free experience for our customers, including those who requested specific support and assistance.

-

Product descriptions from the supplier

Warning/DisclaimerThis product has acquired the relevant product qualification(s)/license(s) of certain applicable country/countries.View more

Overview

Video Description

Fire resistant 10mm 16mm twin wall multiwall polycarbonate sheet greenhouse panelMaterial

Virgin PC Warranty

10 years, Grade A quality Thickness

4mm,6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm Width

1220mm 2100mm or can be customized Length

5800mm,12000mm,11800mm,6000mm or can be customized Popular Size

1.22*2.44m,2.1*5.8m,2.1*11.6m,customized Color

Clear, Milk white, Green, Dark blue, Lake Blue, Brown or Customized Features

Light weight: only 1/2 of the glass of the same thickness. High light transmission: up to 88%

Anti-ultraviolet: 50 micron or any UV thickness is added for free.UV protection both sides, or one side.

High impact strength and tensile strength

Fireproof

Thermal insulation

Sound insulation

Application

Bus stop shelter, Building material, Greenhouse, Car garage tents, Advertising boards,Transportation airline, Swimming pool Cover,etc.

Company Type

Manufacturer of polycarbonate sheet Factory Location

Baoding, Hebei province, China Service

Free sample for testing. Accept OEM/ODM.

24hours instant and comfortable customer service.

Shipping status notification during delivery.

Promotion price

%

Reviews

Clear filtersThere are no reviews yet.