Polycarbonate Sheet Bending: Tips and Tricks for Success

Selecting the Right Type of Polycarbonate Sheet for Bending

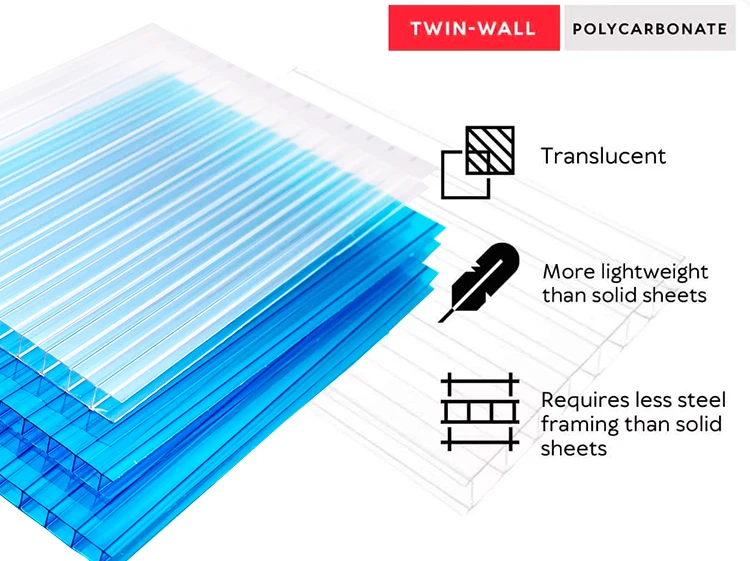

When it comes to bending polycarbonate sheets, choosing the right type is crucial. The most common types are solid polycarbonate sheets and multi-wall polycarbonate sheets. Solid sheets are more rigid and offer better UV protection, making them ideal for applications requiring high transparency and durability. Multi-wall sheets, on the other hand, provide excellent insulation properties and are lighter in weight, which makes them perfect for roofing and glazing projects. Before starting your project, consider the specific requirements of your application to select the appropriate type of polycarbonate sheet.

Preparing the Material for Bending

Proper preparation is key to achieving a successful bend. Begin by cleaning the surface of the polycarbonate sheet thoroughly to remove any dirt or debris that could interfere with the bending process. Next, mark the bend line using a fine-tipped marker or a scoring tool to ensure accuracy. It’s also advisable to pre-drill holes at the bend points if you’re working with thicker sheets to prevent cracking during the bending process. This step can significantly reduce the risk of material failure and enhance the longevity of your final product.

Applying Heat Correctly

Heat is essential for bending polycarbonate sheets as it softens the material, allowing it to be shaped easily. However, applying too much heat can cause the sheet to warp or become discolored. A heat gun or infrared heater is typically used for this purpose. Hold the heat source about 6-8 inches away from the sheet and move it slowly and evenly along the marked line. Be cautious not to focus too much heat in one spot for an extended period, as this can lead to thermal stress and damage the sheet. Regularly check the flexibility of the sheet by gently bending it until it reaches the desired angle. For precise control, a temperature-controlled oven can be used, especially for larger projects or complex bends.

Ensuring Structural Integrity and Aesthetic Appeal

Once the sheet has been bent to the desired shape, allow it to cool gradually to maintain its new form. Rapid cooling can result in uneven shrinkage, causing warping or cracking. Placing the bent sheet in a controlled environment, such as a temperature-controlled room, can help achieve uniform cooling. To further enhance the structural integrity, consider reinforcing the bent area with additional supports or fasteners. Additionally, applying a protective coating can help maintain the aesthetic appeal of the polycarbonate sheet, protecting it from scratches and UV damage. Regular maintenance and cleaning will also contribute to the longevity and appearance of your final product.

Reference

Bending Polycarbonate Sheets: A Comprehensive Guide

- Durable and Long-Lasting: Our Transparent Support Clear Polycarbonate Smoked Multiwall Twinwall Plastic Roof Sheet Hollow Greenhouse Panels offer a 10-year guarantee, ensuring that your investment lasts for years to come, providing peace of mind for our valued customer.

- Customizable Options: We cater to diverse needs by offering various thicknesses (3mm-20mm), widths (1220mm and 2100mm), and colors (clear, green, blue, brown, and opal) to match your specific requirements, including customized solutions as requested by the customer.

- Multi-Functional: Our product is suitable for various applications such as greenhouse skylights, carports, awnings, and roofing, allowing you to utilize a single product for multiple purposes and projects, including golf training aids in sports and entertainment.

- Advanced Features: Our polycarbonate sheet boasts impressive features such as anti-aging, thermal insulation, impact resistance, and fire resistance, ensuring a safe and efficient use of the product in various settings.

- Comprehensive After-Sales Support: We provide online technical support, onsite installation, onsite training, and installation instructions to guarantee a seamless and hassle-free experience for our customers, including those who requested specific support and assistance.

-

Product descriptions from the supplier

Warning/DisclaimerThis product has acquired the relevant product qualification(s)/license(s) of certain applicable country/countries.View more

Overview

Video Description

Fire resistant 10mm 16mm twin wall multiwall polycarbonate sheet greenhouse panelMaterial

Virgin PC Warranty

10 years, Grade A quality Thickness

4mm,6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm Width

1220mm 2100mm or can be customized Length

5800mm,12000mm,11800mm,6000mm or can be customized Popular Size

1.22*2.44m,2.1*5.8m,2.1*11.6m,customized Color

Clear, Milk white, Green, Dark blue, Lake Blue, Brown or Customized Features

Light weight: only 1/2 of the glass of the same thickness. High light transmission: up to 88%

Anti-ultraviolet: 50 micron or any UV thickness is added for free.UV protection both sides, or one side.

High impact strength and tensile strength

Fireproof

Thermal insulation

Sound insulation

Application

Bus stop shelter, Building material, Greenhouse, Car garage tents, Advertising boards,Transportation airline, Swimming pool Cover,etc.

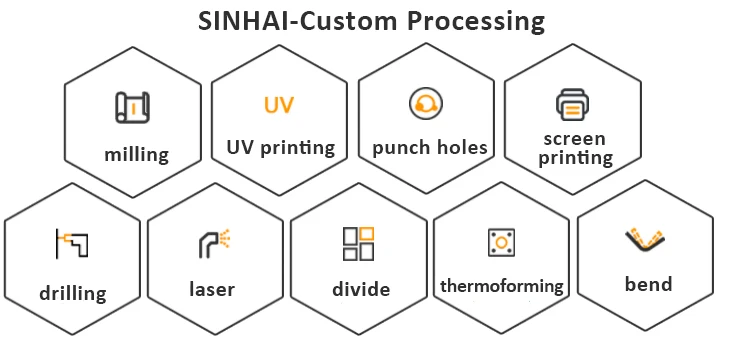

Company Type

Manufacturer of polycarbonate sheet Factory Location

Baoding, Hebei province, China Service

Free sample for testing. Accept OEM/ODM.

24hours instant and comfortable customer service.

Shipping status notification during delivery.

Promotion price

%

Reviews

Clear filtersThere are no reviews yet.