Types of Plastic Building Materials

Introduction to Plastic Building Materials

Plastic building materials have become increasingly popular in recent years due to their versatility, durability, and cost-effectiveness. They are used extensively in various construction projects ranging from residential homes to large commercial buildings. This article will delve into some of the most common types of plastic building materials, including Polyvinyl Chloride (PVC), High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), and others. We will explore their unique properties, advantages, and typical applications in the construction industry.

Polyvinyl Chloride (PVC)

PVC is one of the most widely used plastics in construction. It is known for its excellent resistance to chemicals, weathering, and corrosion. PVC comes in two main forms: rigid and flexible. Rigid PVC is often used for pipes, conduits, and window frames due to its strength and dimensional stability. Flexible PVC, on the other hand, is commonly used for flooring, roofing membranes, and electrical insulation because of its flexibility and water resistance.

High-Density Polyethylene (HDPE)

HDPE is a strong, durable, and lightweight plastic that is ideal for outdoor applications. It has excellent resistance to moisture, chemicals, and impact. In construction, HDPE is frequently used for piping systems, drainage pipes, and geomembranes for containment structures. Its chemical inertness makes it particularly suitable for handling aggressive substances like acids and solvents. Additionally, HDPE is recyclable, making it an environmentally friendly choice.

Low-Density Polyethylene (LDPE)

LDPE is softer and more flexible than HDPE, with good transparency and moisture barrier properties. It is commonly used in thin films and sheets for packaging, but it also finds applications in construction, such as vapor barriers, insulation, and waterproofing membranes. LDPE’s flexibility allows it to conform to irregular surfaces, making it useful for sealing gaps and joints.

Other Types of Plastic Building Materials

Besides PVC, HDPE, and LDPE, there are several other types of plastic building materials worth mentioning. For instance, Polypropylene (PP) is another thermoplastic polymer that is used in construction for its high strength-to-weight ratio and resistance to fatigue. It is often employed in the production of fibers, ropes, and geotextiles. Another notable material is Acrylonitrile Butadiene Styrene (ABS), which is used for piping, enclosures, and fittings due to its toughness and impact resistance.

Conclusion

The use of plastic building materials has revolutionized the construction industry by offering a wide range of benefits over traditional materials. From PVC’s versatility in framing and piping to HDPE’s robustness in drainage systems, each type of plastic brings unique properties that enhance the performance and longevity of construction projects. As sustainability becomes a higher priority, the recyclability and environmental impact of these materials continue to be important considerations.

Reference

Building With Plastics – A Guide to Understanding Plastic Building Products

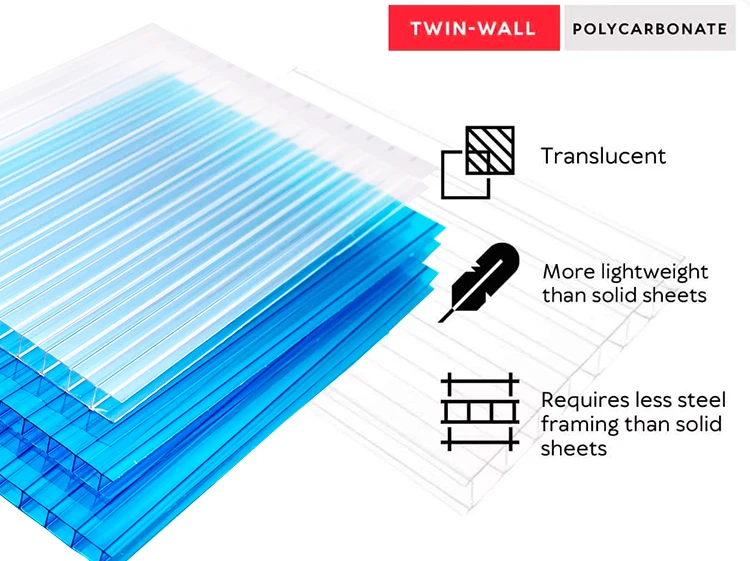

- Durable and Long-Lasting: Our Transparent Support Clear Polycarbonate Smoked Multiwall Twinwall Plastic Roof Sheet Hollow Greenhouse Panels offer a 10-year guarantee, ensuring that your investment lasts for years to come, providing peace of mind for our valued customer.

- Customizable Options: We cater to diverse needs by offering various thicknesses (3mm-20mm), widths (1220mm and 2100mm), and colors (clear, green, blue, brown, and opal) to match your specific requirements, including customized solutions as requested by the customer.

- Multi-Functional: Our product is suitable for various applications such as greenhouse skylights, carports, awnings, and roofing, allowing you to utilize a single product for multiple purposes and projects, including golf training aids in sports and entertainment.

- Advanced Features: Our polycarbonate sheet boasts impressive features such as anti-aging, thermal insulation, impact resistance, and fire resistance, ensuring a safe and efficient use of the product in various settings.

- Comprehensive After-Sales Support: We provide online technical support, onsite installation, onsite training, and installation instructions to guarantee a seamless and hassle-free experience for our customers, including those who requested specific support and assistance.

-

Product descriptions from the supplier

Warning/DisclaimerThis product has acquired the relevant product qualification(s)/license(s) of certain applicable country/countries.View more

Overview

Video Description

Fire resistant 10mm 16mm twin wall multiwall polycarbonate sheet greenhouse panelMaterial

Virgin PC Warranty

10 years, Grade A quality Thickness

4mm,6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm Width

1220mm 2100mm or can be customized Length

5800mm,12000mm,11800mm,6000mm or can be customized Popular Size

1.22*2.44m,2.1*5.8m,2.1*11.6m,customized Color

Clear, Milk white, Green, Dark blue, Lake Blue, Brown or Customized Features

Light weight: only 1/2 of the glass of the same thickness. High light transmission: up to 88%

Anti-ultraviolet: 50 micron or any UV thickness is added for free.UV protection both sides, or one side.

High impact strength and tensile strength

Fireproof

Thermal insulation

Sound insulation

Application

Bus stop shelter, Building material, Greenhouse, Car garage tents, Advertising boards,Transportation airline, Swimming pool Cover,etc.

Company Type

Manufacturer of polycarbonate sheet Factory Location

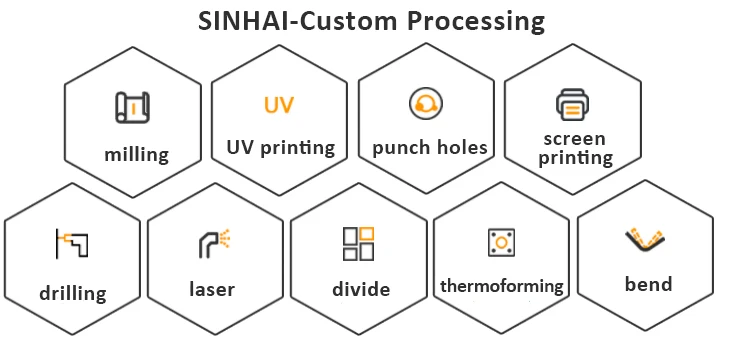

Baoding, Hebei province, China Service

Free sample for testing. Accept OEM/ODM.

24hours instant and comfortable customer service.

Shipping status notification during delivery.

Promotion price

%

Reviews

Clear filtersThere are no reviews yet.