Step-by-Step Guide: Fixing Polycarbonate Sheets

Introduction

Polycarbonate sheets are widely used in construction and manufacturing due to their high impact resistance, light weight, and transparency. However, they can suffer from various issues such as cracks, scratches, or delamination over time. This guide will walk you through identifying common problems, selecting appropriate materials and tools, and providing clear instructions on how to fix these issues effectively. Whether you’re a DIY enthusiast or a professional, this comprehensive tutorial will help you achieve a seamless finish on your polycarbonate sheets.

Identifying Common Issues

Before diving into the repair process, it’s crucial to identify the specific issue with your polycarbonate sheet. Common problems include small cracks, scratches, and larger fractures. Each of these issues requires a different approach in terms of materials and techniques. For instance, small scratches might be polished out, while larger cracks may need to be filled and reinforced with an adhesive. Understanding the nature of the problem is the first step towards effective repair.

Recommended Materials and Tools

To tackle these issues, you’ll need the following materials and tools:

- Adhesive: A suitable epoxy or polyurethane-based adhesive designed for polycarbonate materials.

- Filling Compound: A flexible filler that matches the color of your polycarbonate sheet.

- Polishing Compound: A fine-grit compound for smoothing and shining the surface.

- Sandpaper: Various grits (from 240 to 2000) for sanding down rough edges or surfaces.

- Cleaning Supplies: Isopropyl alcohol and lint-free cloths for cleaning the area before and after repairs.

- Applicators: Brushes, spatulas, and applicator sticks for precise application of adhesives and fillers.

Fixing Adhesive Problems

When dealing with cracks that require bonding, start by thoroughly cleaning both sides of the crack using isopropyl alcohol and lint-free cloths. Apply the adhesive evenly along the crack, ensuring there are no air bubbles. Clamp the sheet together if necessary and allow the adhesive to cure according to the manufacturer’s instructions. After curing, remove any excess adhesive with a sharp blade or sandpaper.

Filling Cracks and Scratches

For smaller cracks and scratches, use a flexible filler compound. Apply it directly onto the affected area, ensuring it fills the gap completely. Smooth out the filler with a spatula or brush until it is level with the surrounding surface. Once the filler has dried, lightly sand the area using progressively finer grits of sandpaper until it blends seamlessly with the rest of the sheet. Clean the area again with isopropyl alcohol before moving on to the next step.

Polishing for a Seamless Finish

The final step involves polishing the repaired areas to ensure a smooth and glossy finish. Start with a coarser grit sandpaper to remove any remaining imperfections, then move to progressively finer grits up to 2000. Use a polishing compound specifically designed for polycarbonate materials, applying it with a soft cloth or buffing wheel. Buff until the surface shines and feels smooth to the touch.

Conclusion

By following these steps, you can effectively repair and restore your polycarbonate sheets to their original condition. Remember that patience and precision are key throughout the entire process. With the right materials, tools, and techniques, even the most challenging repairs can be managed successfully. Whether you’re repairing a greenhouse cover, a sign, or any other polycarbonate item, this guide should provide all the information you need to get the job done right.

Reference

Engineering Toolbox – Polycarbonate Properties

Popular Mechanics – How to Fix Cracked Polycarbonate Sheets

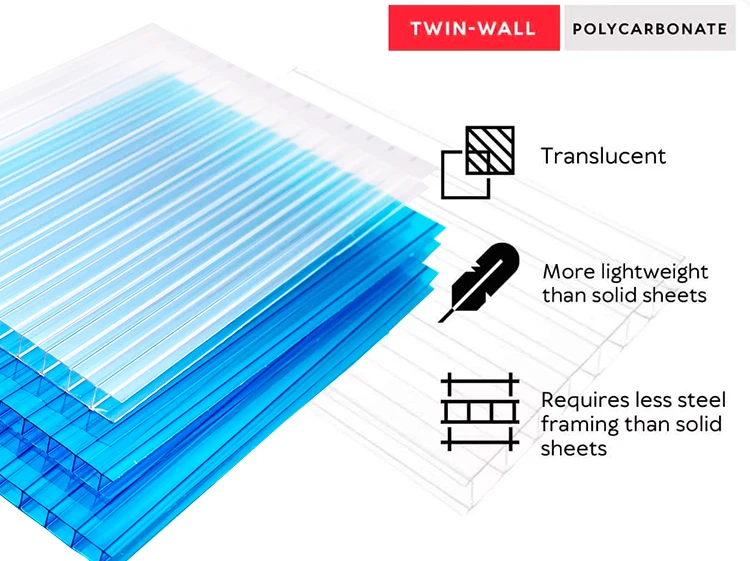

- Durable and Long-Lasting: Our Transparent Support Clear Polycarbonate Smoked Multiwall Twinwall Plastic Roof Sheet Hollow Greenhouse Panels offer a 10-year guarantee, ensuring that your investment lasts for years to come, providing peace of mind for our valued customer.

- Customizable Options: We cater to diverse needs by offering various thicknesses (3mm-20mm), widths (1220mm and 2100mm), and colors (clear, green, blue, brown, and opal) to match your specific requirements, including customized solutions as requested by the customer.

- Multi-Functional: Our product is suitable for various applications such as greenhouse skylights, carports, awnings, and roofing, allowing you to utilize a single product for multiple purposes and projects, including golf training aids in sports and entertainment.

- Advanced Features: Our polycarbonate sheet boasts impressive features such as anti-aging, thermal insulation, impact resistance, and fire resistance, ensuring a safe and efficient use of the product in various settings.

- Comprehensive After-Sales Support: We provide online technical support, onsite installation, onsite training, and installation instructions to guarantee a seamless and hassle-free experience for our customers, including those who requested specific support and assistance.

-

Product descriptions from the supplier

Warning/DisclaimerThis product has acquired the relevant product qualification(s)/license(s) of certain applicable country/countries.View more

Overview

Video Description

Fire resistant 10mm 16mm twin wall multiwall polycarbonate sheet greenhouse panelMaterial

Virgin PC Warranty

10 years, Grade A quality Thickness

4mm,6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm Width

1220mm 2100mm or can be customized Length

5800mm,12000mm,11800mm,6000mm or can be customized Popular Size

1.22*2.44m,2.1*5.8m,2.1*11.6m,customized Color

Clear, Milk white, Green, Dark blue, Lake Blue, Brown or Customized Features

Light weight: only 1/2 of the glass of the same thickness. High light transmission: up to 88%

Anti-ultraviolet: 50 micron or any UV thickness is added for free.UV protection both sides, or one side.

High impact strength and tensile strength

Fireproof

Thermal insulation

Sound insulation

Application

Bus stop shelter, Building material, Greenhouse, Car garage tents, Advertising boards,Transportation airline, Swimming pool Cover,etc.

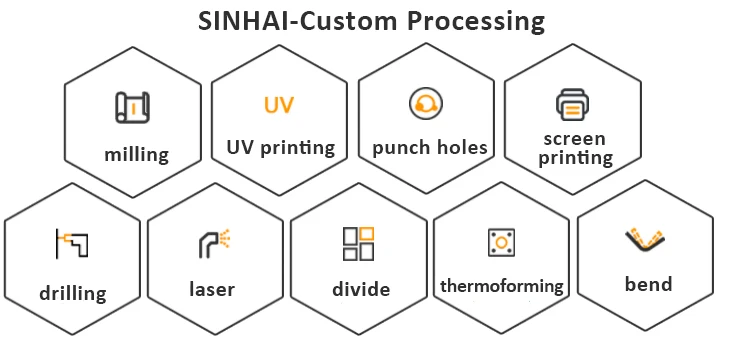

Company Type

Manufacturer of polycarbonate sheet Factory Location

Baoding, Hebei province, China Service

Free sample for testing. Accept OEM/ODM.

24hours instant and comfortable customer service.

Shipping status notification during delivery.

Promotion price

%

Reviews

Clear filtersThere are no reviews yet.