DIY Projects: Polycarbonate Sheets and Screws from Bunnings

Introduction

Polycarbonate sheets are a versatile material used in various DIY projects due to their durability, impact resistance, and light weight. When sourced from a reliable supplier like Bunnings, these sheets can be an excellent choice for projects ranging from greenhouses to roofing. However, using the right screws is equally important to ensure the longevity of your project. In this article, we will provide detailed step-by-step instructions on how to use polycarbonate sheets and screws effectively, highlighting practical advice and common pitfalls to avoid.

Choosing the Right Polycarbonate Sheets and Screws

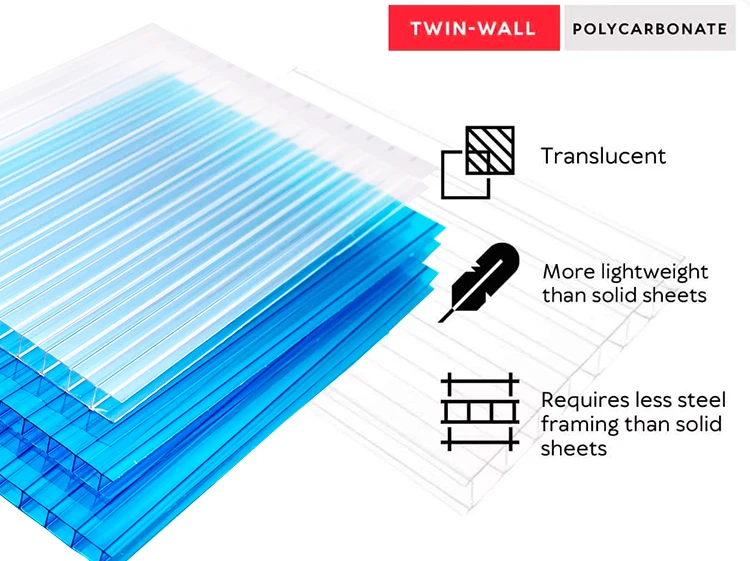

Before you start your DIY project, it’s crucial to choose the right type of polycarbonate sheets and screws. At Bunnings, you can find a variety of options tailored to different applications. For instance, UV-stabilized polycarbonate sheets are ideal for outdoor projects, while multi-wall sheets offer better insulation. When selecting screws, look for those specifically designed for polycarbonate to prevent cracking. It’s also essential to consider the screw length and diameter, as these should be compatible with the thickness of your chosen sheet.

Step-by-Step Instructions for Installation

Step 1: Prepare Your Workspace

Ensure that your workspace is clean and free from debris. Use a level to mark the points where you will drill holes for the screws. This step is critical to maintain the structural integrity and aesthetic appeal of your project.

Step 2: Drill Pilot Holes

Drilling pilot holes before inserting screws is vital to prevent the polycarbonate from cracking. The size of the drill bit should match the screw diameter. This precaution is particularly important when working with thinner sheets.

Step 3: Insert Screws

When inserting screws, use a power drill or screwdriver at a slow speed to avoid damaging the polycarbonate. Tighten the screws just enough to secure the sheet without applying excessive pressure. Over-tightening can cause the material to crack.

Step 4: Finishing Touches

Once all screws are in place, inspect your work for any signs of damage or misalignment. Applying a clear silicone sealant around the edges can help protect against moisture intrusion and enhance the appearance of your project.

Common Pitfalls to Avoid

One common mistake is not pre-drilling holes, which often leads to cracked sheets. Another pitfall is using screws that are too long or too short, causing uneven pressure distribution or difficulty in securing the sheets. Additionally, over-tightening screws can compromise the integrity of the polycarbonate material. Always refer to the manufacturer’s guidelines for specific recommendations.

Conclusion

By following these detailed steps and avoiding common mistakes, you can successfully complete your DIY projects using polycarbonate sheets and screws from Bunnings. Remember, preparation and attention to detail are key to achieving professional results. With the right materials and techniques, your next project could turn out even better than expected!

Reference

How to Install Polycarbonate Sheets

- Durable and Long-Lasting: Our Transparent Support Clear Polycarbonate Smoked Multiwall Twinwall Plastic Roof Sheet Hollow Greenhouse Panels offer a 10-year guarantee, ensuring that your investment lasts for years to come, providing peace of mind for our valued customer.

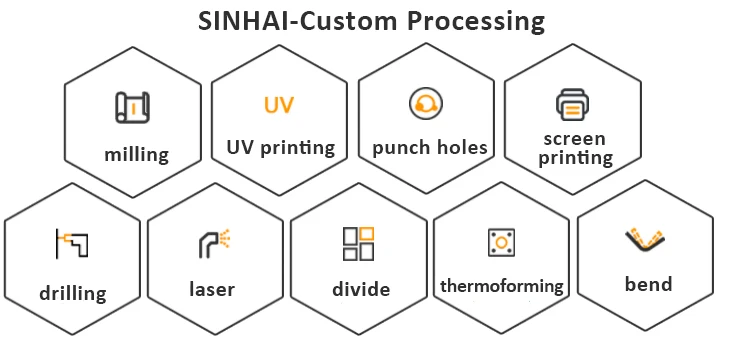

- Customizable Options: We cater to diverse needs by offering various thicknesses (3mm-20mm), widths (1220mm and 2100mm), and colors (clear, green, blue, brown, and opal) to match your specific requirements, including customized solutions as requested by the customer.

- Multi-Functional: Our product is suitable for various applications such as greenhouse skylights, carports, awnings, and roofing, allowing you to utilize a single product for multiple purposes and projects, including golf training aids in sports and entertainment.

- Advanced Features: Our polycarbonate sheet boasts impressive features such as anti-aging, thermal insulation, impact resistance, and fire resistance, ensuring a safe and efficient use of the product in various settings.

- Comprehensive After-Sales Support: We provide online technical support, onsite installation, onsite training, and installation instructions to guarantee a seamless and hassle-free experience for our customers, including those who requested specific support and assistance.

-

Product descriptions from the supplier

Warning/DisclaimerThis product has acquired the relevant product qualification(s)/license(s) of certain applicable country/countries.View more

Overview

Video Description

Fire resistant 10mm 16mm twin wall multiwall polycarbonate sheet greenhouse panelMaterial

Virgin PC Warranty

10 years, Grade A quality Thickness

4mm,6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm Width

1220mm 2100mm or can be customized Length

5800mm,12000mm,11800mm,6000mm or can be customized Popular Size

1.22*2.44m,2.1*5.8m,2.1*11.6m,customized Color

Clear, Milk white, Green, Dark blue, Lake Blue, Brown or Customized Features

Light weight: only 1/2 of the glass of the same thickness. High light transmission: up to 88%

Anti-ultraviolet: 50 micron or any UV thickness is added for free.UV protection both sides, or one side.

High impact strength and tensile strength

Fireproof

Thermal insulation

Sound insulation

Application

Bus stop shelter, Building material, Greenhouse, Car garage tents, Advertising boards,Transportation airline, Swimming pool Cover,etc.

Company Type

Manufacturer of polycarbonate sheet Factory Location

Baoding, Hebei province, China Service

Free sample for testing. Accept OEM/ODM.

24hours instant and comfortable customer service.

Shipping status notification during delivery.

Promotion price

%

Reviews

Clear filtersThere are no reviews yet.