DIY Solutions for Fixing Damaged Polycarbonate Panels

Introduction

Polycarbonate panels are widely used in construction due to their lightweight, high impact resistance, and UV protection. However, these panels can sometimes suffer from cracks or damage. Repairing these damages yourself can save money and time, but it is important to choose the right method for the specific type of damage. This article will discuss common DIY approaches to repair cracked polycarbonate sheets, examining the pros and cons of each method and when they should be applied.

Common DIY Methods for Repairing Cracked Polycarbonate Sheets

Heat Welding

Heat welding involves using a heat gun or soldering iron to melt the edges of the crack and then applying a small amount of polycarbonate adhesive to seal it. This method is particularly effective for smaller cracks. The main advantage of heat welding is that it creates a strong bond, which can last for years if done correctly. However, this method requires precision and practice to avoid overheating and damaging the panel further. It is also essential to ensure that the surface is clean and free from dust before attempting this repair.

Epoxy Resin

Epoxy resin is another popular option for repairing cracked polycarbonate sheets. This method involves mixing an epoxy resin with a hardener and applying it directly to the crack. Once cured, the epoxy provides a strong and durable repair. Epoxy resin is easy to use and can be found at most hardware stores. However, it may not be as flexible as the original material, potentially leading to stress fractures in the future. Additionally, improper application can result in visible marks on the surface of the panel.

Adhesive Tape

For minor cracks or scratches, adhesive tape can be an effective and quick solution. Clear polycarbonate tape can be applied over the damaged area, providing immediate visual improvement. This method is simple and does not require any special tools or skills. However, it is only a temporary fix and may need to be reapplied periodically. Moreover, the tape can affect the clarity and appearance of the panel over time.

Choosing the Right Method

The choice between these methods depends on the severity and location of the damage. Heat welding and epoxy resin are more suitable for deeper or longer cracks, while adhesive tape is better for minor issues. Always consider the intended use of the panel after repair and whether the chosen method will meet those requirements.

Conclusion

Repairing cracked polycarbonate sheets can be a cost-effective solution when done correctly. By understanding the pros and cons of each method, you can choose the best approach for your specific situation. Whether you opt for heat welding, epoxy resin, or adhesive tape, always prioritize safety and follow proper techniques to achieve the best results.

Reference

How to Repair Cracks in Polycarbonate Sheets

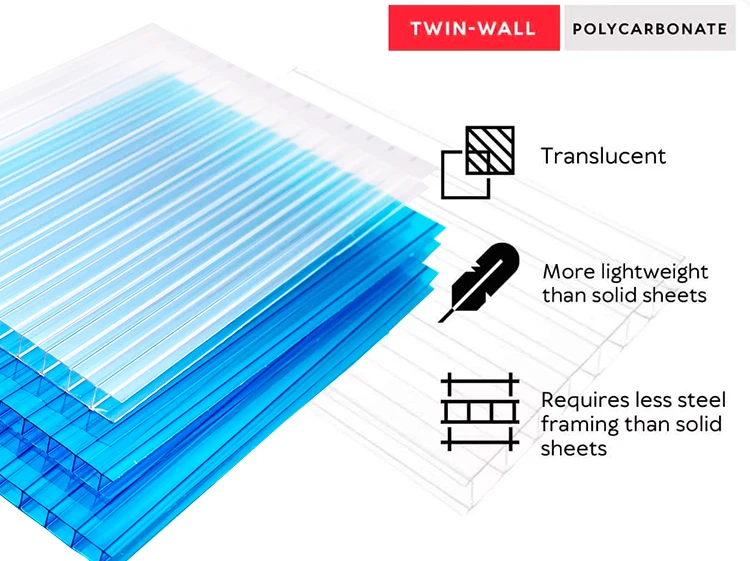

- Durable and Long-Lasting: Our Transparent Support Clear Polycarbonate Smoked Multiwall Twinwall Plastic Roof Sheet Hollow Greenhouse Panels offer a 10-year guarantee, ensuring that your investment lasts for years to come, providing peace of mind for our valued customer.

- Customizable Options: We cater to diverse needs by offering various thicknesses (3mm-20mm), widths (1220mm and 2100mm), and colors (clear, green, blue, brown, and opal) to match your specific requirements, including customized solutions as requested by the customer.

- Multi-Functional: Our product is suitable for various applications such as greenhouse skylights, carports, awnings, and roofing, allowing you to utilize a single product for multiple purposes and projects, including golf training aids in sports and entertainment.

- Advanced Features: Our polycarbonate sheet boasts impressive features such as anti-aging, thermal insulation, impact resistance, and fire resistance, ensuring a safe and efficient use of the product in various settings.

- Comprehensive After-Sales Support: We provide online technical support, onsite installation, onsite training, and installation instructions to guarantee a seamless and hassle-free experience for our customers, including those who requested specific support and assistance.

-

Product descriptions from the supplier

Warning/DisclaimerThis product has acquired the relevant product qualification(s)/license(s) of certain applicable country/countries.View more

Overview

Video Description

Fire resistant 10mm 16mm twin wall multiwall polycarbonate sheet greenhouse panelMaterial

Virgin PC Warranty

10 years, Grade A quality Thickness

4mm,6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm Width

1220mm 2100mm or can be customized Length

5800mm,12000mm,11800mm,6000mm or can be customized Popular Size

1.22*2.44m,2.1*5.8m,2.1*11.6m,customized Color

Clear, Milk white, Green, Dark blue, Lake Blue, Brown or Customized Features

Light weight: only 1/2 of the glass of the same thickness. High light transmission: up to 88%

Anti-ultraviolet: 50 micron or any UV thickness is added for free.UV protection both sides, or one side.

High impact strength and tensile strength

Fireproof

Thermal insulation

Sound insulation

Application

Bus stop shelter, Building material, Greenhouse, Car garage tents, Advertising boards,Transportation airline, Swimming pool Cover,etc.

Company Type

Manufacturer of polycarbonate sheet Factory Location

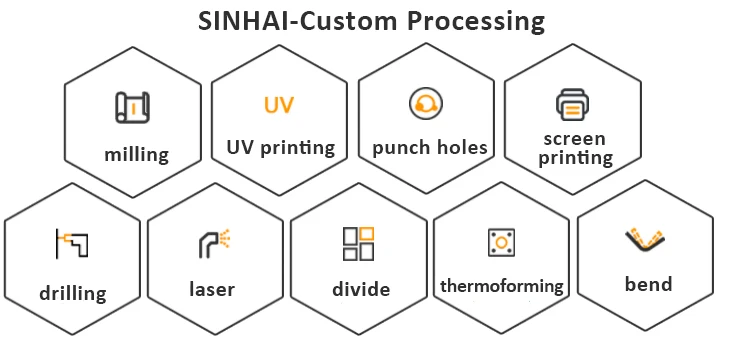

Baoding, Hebei province, China Service

Free sample for testing. Accept OEM/ODM.

24hours instant and comfortable customer service.

Shipping status notification during delivery.

Promotion price

%

Reviews

Clear filtersThere are no reviews yet.