Polycarbonate Sheet Bending

Introduction

Polycarbonate sheets are widely used in various applications due to their excellent properties such as impact resistance, transparency, and flexibility. One of the essential skills when working with these materials is the ability to bend them into desired shapes. This article provides a comprehensive guide on different bending techniques for polycarbonate sheets, including hot bending, cold bending, and vacuum forming. We will discuss the tools required, safety precautions, and practical tips for achieving professional results.

Hot Bending Technique

Hot bending is a common method used to form polycarbonate sheets into curved or angled shapes. The process involves heating the material until it becomes pliable enough to be bent without cracking. To perform hot bending, you will need a heat source like an infrared heater or a gas torch, along with bending irons or molds to shape the heated material. Safety precautions include wearing protective gear such as gloves and goggles to prevent burns and eye injuries. It’s crucial to maintain consistent temperature control during the heating process to avoid overheating and damaging the material.

Cold Bending Technique

Cold bending is another technique that can be used for polycarbonate sheets, especially when precise angles are required. Unlike hot bending, this method does not involve heating the material. Instead, cold bending relies on mechanical force applied by specialized equipment or hand tools. For instance, a press brake can be used to create sharp bends at specific angles. While cold bending is less likely to cause thermal stress on the material, it requires careful calibration of the bending force to prevent cracking or distortion. Always refer to the manufacturer’s specifications for the minimum radius of curvature to avoid damaging the polycarbonate sheet.

Vacuum Forming Technique

Vacuum forming is an efficient way to create complex shapes from polycarbonate sheets. This process involves placing a heated sheet over a mold and then applying vacuum pressure to draw the material tightly against the mold’s contours. The key advantage of vacuum forming is its ability to produce uniform thickness across the formed part. Equipment needed includes a vacuum former machine, heating elements, and a mold. Safety measures include ensuring proper ventilation to manage fumes produced during heating and using appropriate protective clothing.

Practical Tips for Achieving Professional Results

To achieve professional results when bending polycarbonate sheets, consider the following tips: Always test your bending technique on scrap material before working on the final piece; use lubricants like silicone spray to reduce friction and prevent scratches during the bending process; and allow the bent material to cool gradually to avoid warping or cracking. Regular maintenance of your tools and equipment is also important to ensure precision and efficiency.

Reference

Bending Polycarbonate Sheets: Techniques and Tips

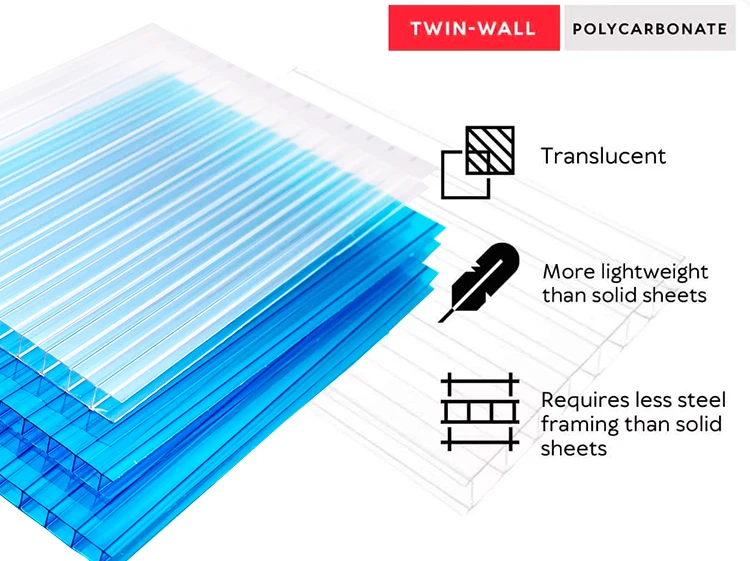

- Durable and Long-Lasting: Our Transparent Support Clear Polycarbonate Smoked Multiwall Twinwall Plastic Roof Sheet Hollow Greenhouse Panels offer a 10-year guarantee, ensuring that your investment lasts for years to come, providing peace of mind for our valued customer.

- Customizable Options: We cater to diverse needs by offering various thicknesses (3mm-20mm), widths (1220mm and 2100mm), and colors (clear, green, blue, brown, and opal) to match your specific requirements, including customized solutions as requested by the customer.

- Multi-Functional: Our product is suitable for various applications such as greenhouse skylights, carports, awnings, and roofing, allowing you to utilize a single product for multiple purposes and projects, including golf training aids in sports and entertainment.

- Advanced Features: Our polycarbonate sheet boasts impressive features such as anti-aging, thermal insulation, impact resistance, and fire resistance, ensuring a safe and efficient use of the product in various settings.

- Comprehensive After-Sales Support: We provide online technical support, onsite installation, onsite training, and installation instructions to guarantee a seamless and hassle-free experience for our customers, including those who requested specific support and assistance.

-

Product descriptions from the supplier

Warning/DisclaimerThis product has acquired the relevant product qualification(s)/license(s) of certain applicable country/countries.View more

Overview

Video Description

Fire resistant 10mm 16mm twin wall multiwall polycarbonate sheet greenhouse panelMaterial

Virgin PC Warranty

10 years, Grade A quality Thickness

4mm,6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm Width

1220mm 2100mm or can be customized Length

5800mm,12000mm,11800mm,6000mm or can be customized Popular Size

1.22*2.44m,2.1*5.8m,2.1*11.6m,customized Color

Clear, Milk white, Green, Dark blue, Lake Blue, Brown or Customized Features

Light weight: only 1/2 of the glass of the same thickness. High light transmission: up to 88%

Anti-ultraviolet: 50 micron or any UV thickness is added for free.UV protection both sides, or one side.

High impact strength and tensile strength

Fireproof

Thermal insulation

Sound insulation

Application

Bus stop shelter, Building material, Greenhouse, Car garage tents, Advertising boards,Transportation airline, Swimming pool Cover,etc.

Company Type

Manufacturer of polycarbonate sheet Factory Location

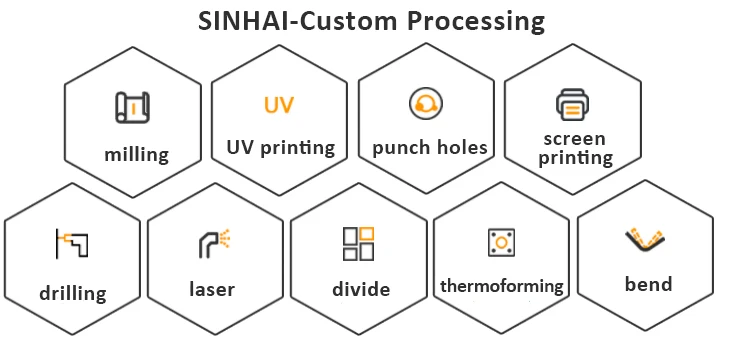

Baoding, Hebei province, China Service

Free sample for testing. Accept OEM/ODM.

24hours instant and comfortable customer service.

Shipping status notification during delivery.

Promotion price

%

Reviews

Clear filtersThere are no reviews yet.