Polycarbonate Sheet Bonding: Tips for Achieving Optimal Results

Selecting the Right Adhesive

When it comes to polycarbonate sheet bonding, choosing the correct adhesive is paramount. Polycarbonate sheets are known for their strength and durability, but they require specific adhesives to ensure a strong bond. Acrylic-based adhesives are often recommended due to their flexibility and resistance to ultraviolet (UV) light, which helps prevent yellowing over time. Epoxy resins also work well for applications requiring high strength and chemical resistance. It’s important to consider the environmental conditions in which your bonded sheets will be used, as this can affect the choice of adhesive.

Preparing the Surfaces

Proper surface preparation is crucial for achieving optimal results in polycarbonate sheet bonding. Begin by thoroughly cleaning both surfaces with a mild detergent and water solution to remove any dirt, dust, or oils. Rinse with clean water and allow the surfaces to dry completely. Sanding the edges lightly can help improve adhesion, but be cautious not to create scratches that could weaken the bond. After sanding, wipe down the surfaces again to remove any debris before applying the adhesive.

Maintaining Proper Temperature Conditions

Temperature plays a significant role in the effectiveness of the bonding process. Ideally, bonding should take place at room temperature (around 20-25°C). Higher temperatures can cause the adhesive to cure too quickly, leading to improper bonding, while lower temperatures can slow down the curing process. Ensure that both the polycarbonate sheets and the adhesive are at room temperature before starting the bonding process. Additionally, keeping the work area free from drafts can help maintain consistent temperature conditions during the bonding process.

Post-Bonding Treatments

After bonding, it’s essential to allow sufficient time for the adhesive to cure fully. This typically takes between 24 to 48 hours, depending on the type of adhesive used. During this period, avoid subjecting the bonded sheets to excessive stress or pressure. If necessary, use clamps or weights to hold the sheets together until the adhesive has cured. Once cured, inspect the bond for any imperfections such as bubbles or weak spots. Regular maintenance checks can help identify any issues early on and extend the life of your bonded polycarbonate sheets.

Avoiding Common Mistakes

Several common mistakes can undermine the success of your polycarbonate sheet bonding project. One frequent issue is insufficient surface preparation, which can lead to weak bonds. Another mistake is using the wrong type of adhesive for the application, resulting in poor adhesion or premature failure. Overlooking temperature control during the bonding process can also result in suboptimal bonding. Always follow the manufacturer’s instructions carefully and double-check all steps to avoid these pitfalls.

Troubleshooting Advice

If you encounter issues like bubbles or weak bonds, there are several troubleshooting steps you can take. For bubbles, ensure that the surfaces are perfectly flat and free from contaminants. Use a syringe or needle to carefully remove air bubbles if they appear after bonding. For weak bonds, review the surface preparation and adhesive selection processes. Reapplying the adhesive with proper surface preparation may solve the problem. In cases where the bond remains weak, consulting the adhesive manufacturer for further guidance might be necessary.

Reference

- Durable and Long-Lasting: Our Transparent Support Clear Polycarbonate Smoked Multiwall Twinwall Plastic Roof Sheet Hollow Greenhouse Panels offer a 10-year guarantee, ensuring that your investment lasts for years to come, providing peace of mind for our valued customer.

- Customizable Options: We cater to diverse needs by offering various thicknesses (3mm-20mm), widths (1220mm and 2100mm), and colors (clear, green, blue, brown, and opal) to match your specific requirements, including customized solutions as requested by the customer.

- Multi-Functional: Our product is suitable for various applications such as greenhouse skylights, carports, awnings, and roofing, allowing you to utilize a single product for multiple purposes and projects, including golf training aids in sports and entertainment.

- Advanced Features: Our polycarbonate sheet boasts impressive features such as anti-aging, thermal insulation, impact resistance, and fire resistance, ensuring a safe and efficient use of the product in various settings.

- Comprehensive After-Sales Support: We provide online technical support, onsite installation, onsite training, and installation instructions to guarantee a seamless and hassle-free experience for our customers, including those who requested specific support and assistance.

-

Product descriptions from the supplier

Warning/DisclaimerThis product has acquired the relevant product qualification(s)/license(s) of certain applicable country/countries.View more

Overview

Video Description

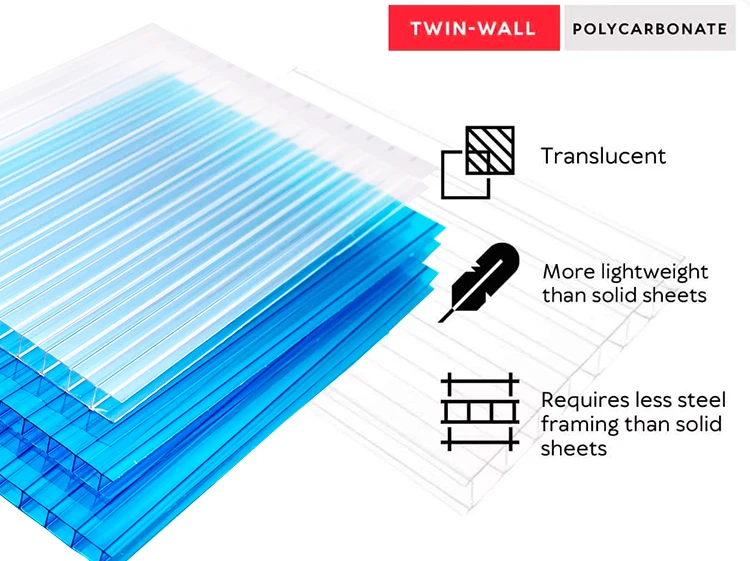

Fire resistant 10mm 16mm twin wall multiwall polycarbonate sheet greenhouse panelMaterial

Virgin PC Warranty

10 years, Grade A quality Thickness

4mm,6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm Width

1220mm 2100mm or can be customized Length

5800mm,12000mm,11800mm,6000mm or can be customized Popular Size

1.22*2.44m,2.1*5.8m,2.1*11.6m,customized Color

Clear, Milk white, Green, Dark blue, Lake Blue, Brown or Customized Features

Light weight: only 1/2 of the glass of the same thickness. High light transmission: up to 88%

Anti-ultraviolet: 50 micron or any UV thickness is added for free.UV protection both sides, or one side.

High impact strength and tensile strength

Fireproof

Thermal insulation

Sound insulation

Application

Bus stop shelter, Building material, Greenhouse, Car garage tents, Advertising boards,Transportation airline, Swimming pool Cover,etc.

Company Type

Manufacturer of polycarbonate sheet Factory Location

Baoding, Hebei province, China Service

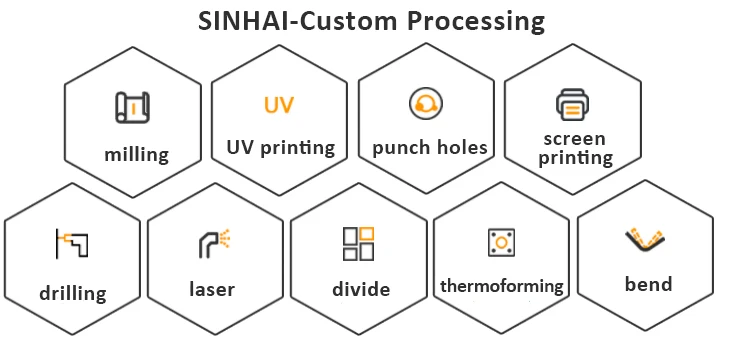

Free sample for testing. Accept OEM/ODM.

24hours instant and comfortable customer service.

Shipping status notification during delivery.

Promotion price

%

Reviews

Clear filtersThere are no reviews yet.