Polycarbonate Sheet Bulletproof: Manufacturing Process, Properties, and Applications

Introduction to Polycarbonate Sheets

Polycarbonate sheets are a versatile material widely used in various industries due to their exceptional strength and transparency. Among their many applications, one standout use is as bulletproof materials, which provide high levels of protection against ballistic threats. This article delves into the manufacturing process of these specialized sheets, examines their unique physical properties, and explores real-world instances where they have been effectively utilized.

Manufacturing Process of Polycarbonate Sheets Bulletproof

The production of bulletproof polycarbonate sheets involves a combination of advanced engineering techniques and precise material selection. The process begins with the polymerization of bisphenol A (BPA) and phosgene, resulting in a clear, amorphous thermoplastic. This raw material undergoes further processing through extrusion or injection molding, shaping it into sheets with varying thicknesses. To achieve bulletproof capabilities, multiple layers of these sheets are often bonded together using a transparent adhesive, creating a multi-layered composite structure. This construction method enhances the overall strength and durability of the final product, making it capable of withstanding significant impacts.

Physical Properties Ideal for Security Applications

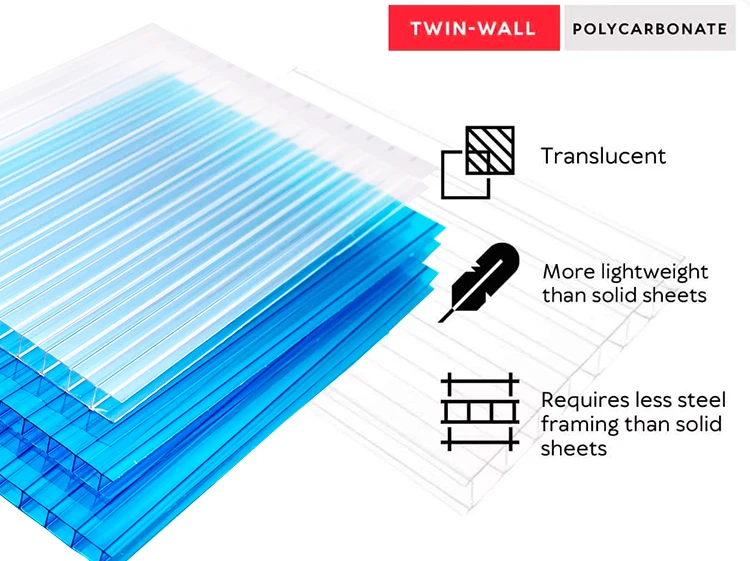

Bulletproof polycarbonate sheets possess several key properties that make them ideal for security applications. Firstly, they exhibit remarkable impact resistance, allowing them to absorb and distribute kinetic energy efficiently. Additionally, these sheets maintain their structural integrity under extreme temperatures, ensuring consistent performance across different environmental conditions. Furthermore, the lightweight nature of polycarbonate reduces the burden on supporting structures while still providing robust protection. Lastly, their optical clarity ensures unobstructed visibility, making them suitable for use in windows, barriers, and other protective installations.

Real-World Examples of Successful Implementations

Bulletproof polycarbonate sheets have been successfully deployed in numerous high-security environments worldwide. For instance, banks and financial institutions often utilize these materials in their teller windows to safeguard employees and customers from potential threats. Similarly, government buildings, embassies, and military facilities frequently incorporate bulletproof panels in their architectural designs to enhance safety measures. In the automotive sector, some luxury vehicles feature reinforced windows made from bullet-resistant polycarbonate, offering occupants an additional layer of protection during emergencies. These practical implementations underscore the effectiveness and reliability of bulletproof polycarbonate sheets in real-life scenarios.

Conclusion

In conclusion, the manufacturing process of bulletproof polycarbonate sheets involves sophisticated techniques aimed at producing highly durable and transparent materials. Their inherent physical properties, such as excellent impact resistance and temperature stability, make them invaluable assets in security applications. From banking establishments to governmental facilities and beyond, bulletproof polycarbonate sheets continue to play a crucial role in safeguarding lives and property. As technology advances, we can expect further improvements in this field, leading to even more innovative solutions for enhancing public safety.

Reference

Encyclopedia Britannica – Polycarbonate Plastic

ScienceDirect – Bulletproof Glass

- Durable and Long-Lasting: Our Transparent Support Clear Polycarbonate Smoked Multiwall Twinwall Plastic Roof Sheet Hollow Greenhouse Panels offer a 10-year guarantee, ensuring that your investment lasts for years to come, providing peace of mind for our valued customer.

- Customizable Options: We cater to diverse needs by offering various thicknesses (3mm-20mm), widths (1220mm and 2100mm), and colors (clear, green, blue, brown, and opal) to match your specific requirements, including customized solutions as requested by the customer.

- Multi-Functional: Our product is suitable for various applications such as greenhouse skylights, carports, awnings, and roofing, allowing you to utilize a single product for multiple purposes and projects, including golf training aids in sports and entertainment.

- Advanced Features: Our polycarbonate sheet boasts impressive features such as anti-aging, thermal insulation, impact resistance, and fire resistance, ensuring a safe and efficient use of the product in various settings.

- Comprehensive After-Sales Support: We provide online technical support, onsite installation, onsite training, and installation instructions to guarantee a seamless and hassle-free experience for our customers, including those who requested specific support and assistance.

-

Product descriptions from the supplier

Warning/DisclaimerThis product has acquired the relevant product qualification(s)/license(s) of certain applicable country/countries.View more

Overview

Video Description

Fire resistant 10mm 16mm twin wall multiwall polycarbonate sheet greenhouse panelMaterial

Virgin PC Warranty

10 years, Grade A quality Thickness

4mm,6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm Width

1220mm 2100mm or can be customized Length

5800mm,12000mm,11800mm,6000mm or can be customized Popular Size

1.22*2.44m,2.1*5.8m,2.1*11.6m,customized Color

Clear, Milk white, Green, Dark blue, Lake Blue, Brown or Customized Features

Light weight: only 1/2 of the glass of the same thickness. High light transmission: up to 88%

Anti-ultraviolet: 50 micron or any UV thickness is added for free.UV protection both sides, or one side.

High impact strength and tensile strength

Fireproof

Thermal insulation

Sound insulation

Application

Bus stop shelter, Building material, Greenhouse, Car garage tents, Advertising boards,Transportation airline, Swimming pool Cover,etc.

Company Type

Manufacturer of polycarbonate sheet Factory Location

Baoding, Hebei province, China Service

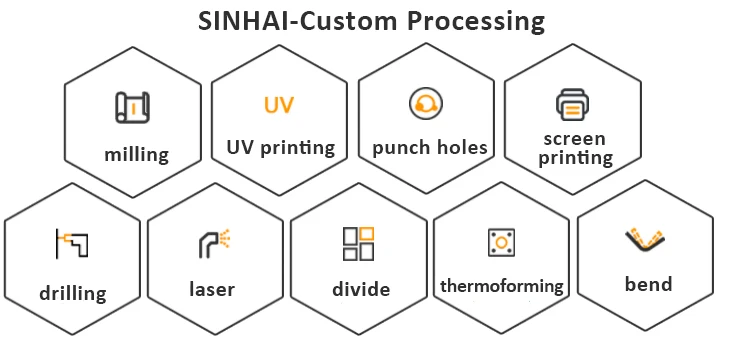

Free sample for testing. Accept OEM/ODM.

24hours instant and comfortable customer service.

Shipping status notification during delivery.

Promotion price

%

Reviews

Clear filtersThere are no reviews yet.