Polycarbonate vs Acrylic Sheets: Which is Best for Your Project?

Introduction

When choosing materials for your next project, two common options that often come up are polycarbonate sheets and acrylic sheets. Both materials offer a range of benefits and have their own unique characteristics. This guide aims to evaluate these two materials based on aspects like ease of fabrication, maintenance requirements, cost-effectiveness, and environmental impact. By understanding the differences between polycarbonate and acrylic sheets, you can make an informed decision about which one is best suited for your specific project needs.

Comparing Polycarbonate and Acrylic Sheets

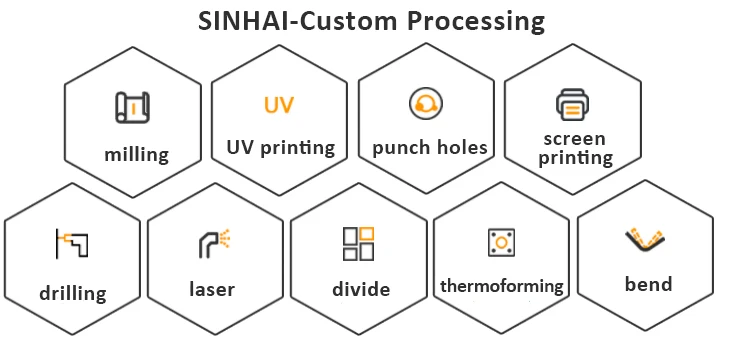

Ease of Fabrication

Both polycarbonate and acrylic sheets can be easily cut, drilled, and shaped using standard woodworking tools. However, polycarbonate has a slight edge in terms of fabrication due to its lower melting point compared to acrylic. This makes it easier to bend and shape without the risk of cracking. For instance, when creating intricate designs or custom shapes, polycarbonate sheets might prove more versatile.

Maintenance Requirements

In terms of maintenance, acrylic sheets generally require less care than polycarbonate. Acrylic is more resistant to scratching and chemicals, making it ideal for applications where appearance needs to be maintained over time. On the other hand, polycarbonate is more susceptible to scratches but offers better resistance to impacts. Therefore, if your project involves frequent handling or exposure to harsh environments, acrylic might be a better choice for longevity.

Cost-effectiveness

When it comes to cost, acrylic sheets are typically less expensive than polycarbonate sheets. However, the overall cost-effectiveness depends on the intended use of the material. For example, if durability and impact resistance are crucial, the higher initial cost of polycarbonate might be justified by its longer lifespan and reduced need for replacement. Referencing a study from Materials Reviews, polycarbonate’s superior impact resistance often makes it a more economical option in the long run.

Environmental Impact

Both materials have their environmental considerations. Acrylic is known for being recyclable, whereas polycarbonate recycling can be more challenging. However, polycarbonate is highly durable and can last much longer than acrylic, potentially reducing waste over time. It’s important to weigh these factors against your project’s sustainability goals. A report from Sustainability Journal provides a detailed analysis of the lifecycle of both materials.

Conclusion

The choice between polycarbonate and acrylic sheets ultimately depends on the specific requirements of your project. If you prioritize ease of fabrication and impact resistance, polycarbonate may be the better option. Conversely, if you are looking for low-maintenance and cost-effective solutions, acrylic could be preferable. Always consider the intended application, budget, and environmental concerns before making a final decision.

Reference

Materials Reviews – Polycarbonate vs Acrylic: A Comprehensive Guide

Sustainability Journal – Evaluating the Environmental Impact of Polycarbonate and Acrylic

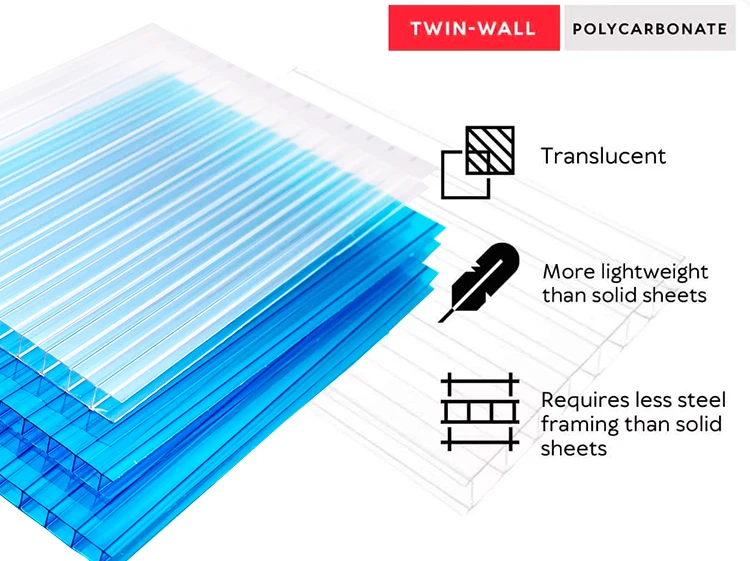

- Durable and Long-Lasting: Our Transparent Support Clear Polycarbonate Smoked Multiwall Twinwall Plastic Roof Sheet Hollow Greenhouse Panels offer a 10-year guarantee, ensuring that your investment lasts for years to come, providing peace of mind for our valued customer.

- Customizable Options: We cater to diverse needs by offering various thicknesses (3mm-20mm), widths (1220mm and 2100mm), and colors (clear, green, blue, brown, and opal) to match your specific requirements, including customized solutions as requested by the customer.

- Multi-Functional: Our product is suitable for various applications such as greenhouse skylights, carports, awnings, and roofing, allowing you to utilize a single product for multiple purposes and projects, including golf training aids in sports and entertainment.

- Advanced Features: Our polycarbonate sheet boasts impressive features such as anti-aging, thermal insulation, impact resistance, and fire resistance, ensuring a safe and efficient use of the product in various settings.

- Comprehensive After-Sales Support: We provide online technical support, onsite installation, onsite training, and installation instructions to guarantee a seamless and hassle-free experience for our customers, including those who requested specific support and assistance.

-

Product descriptions from the supplier

Warning/DisclaimerThis product has acquired the relevant product qualification(s)/license(s) of certain applicable country/countries.View more

Overview

Video Description

Fire resistant 10mm 16mm twin wall multiwall polycarbonate sheet greenhouse panelMaterial

Virgin PC Warranty

10 years, Grade A quality Thickness

4mm,6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm Width

1220mm 2100mm or can be customized Length

5800mm,12000mm,11800mm,6000mm or can be customized Popular Size

1.22*2.44m,2.1*5.8m,2.1*11.6m,customized Color

Clear, Milk white, Green, Dark blue, Lake Blue, Brown or Customized Features

Light weight: only 1/2 of the glass of the same thickness. High light transmission: up to 88%

Anti-ultraviolet: 50 micron or any UV thickness is added for free.UV protection both sides, or one side.

High impact strength and tensile strength

Fireproof

Thermal insulation

Sound insulation

Application

Bus stop shelter, Building material, Greenhouse, Car garage tents, Advertising boards,Transportation airline, Swimming pool Cover,etc.

Company Type

Manufacturer of polycarbonate sheet Factory Location

Baoding, Hebei province, China Service

Free sample for testing. Accept OEM/ODM.

24hours instant and comfortable customer service.

Shipping status notification during delivery.

Promotion price

%

Reviews

Clear filtersThere are no reviews yet.