Polycarbonate vs Plexiglass: Which One Should You Choose?

Introduction

When it comes to selecting transparent materials for various applications, two names often come up in discussions: Polycarbonate and Plexiglass (also known as Acrylic). Both are popular choices due to their versatility, but they each have unique properties that make them suitable for different purposes. This article will delve into the key differences between Polycarbonate sheets and Plexiglass, focusing on factors such as impact resistance, optical clarity, and ease of fabrication. By understanding these distinctions, you can make an informed decision about which material is best suited for your needs.

Impact Resistance

One of the most significant differences between Polycarbonate and Plexiglass is their impact resistance. Polycarbonate is renowned for its superior strength and toughness, making it nearly unbreakable under normal conditions. According to Engineering Toolbox, Polycarbonate can withstand impacts up to 250 times greater than acrylic. This makes it an ideal choice for safety applications, such as bulletproof windows, protective shields, and eyewear. For instance, military-grade goggles and helmets frequently use Polycarbonate due to its ability to absorb high-energy impacts without shattering.

Optical Clarity

While Polycarbonate boasts impressive durability, Plexiglass is generally preferred when optical clarity is a priority. Plexiglass offers higher transparency and less distortion compared to Polycarbonate. It is commonly used in applications where visual aesthetics are crucial, such as display cases, aquariums, and signage. However, it is worth noting that recent advancements in Polycarbonate manufacturing have improved its optical quality, though it still falls short of Plexiglass in this regard. For example, ScienceDirect highlights how newer Polycarbonate formulations have enhanced clarity, making it more competitive in markets requiring clear visuals.

Ease of Fabrication

Both materials are relatively easy to work with, but they require different techniques. Polycarbonate can be easily cut, drilled, and formed using standard woodworking tools, making it accessible even for DIY projects. It also has a lower melting point compared to Plexiglass, which allows for easier bending and shaping. On the other hand, Plexiglass requires more specialized tools and techniques, such as laser cutting, to achieve precise cuts and edges. Despite this, Plexiglass remains a favorite among professional fabricators due to its consistent quality and finish. For example, Plastics Centre provides detailed guidelines on working with Plexiglass, emphasizing the importance of proper tooling and techniques for optimal results.

Case Studies and Examples

To further illustrate the practical applications of these materials, let’s consider a few case studies. In the automotive industry, Polycarbonate is widely used in headlamp lenses due to its impact resistance and light transmission properties. Conversely, Plexiglass is commonly found in aircraft windows, where optical clarity and lightweight design are essential. Additionally, both materials find extensive use in architectural applications, with Polycarbonate being chosen for its robustness in high-traffic areas, while Plexiglass is favored for its aesthetic appeal in interior design projects.

Conclusion

In summary, choosing between Polycarbonate and Plexiglass depends largely on the specific requirements of your project. If you need a material that can withstand extreme impacts and harsh environments, Polycarbonate is the better option. For applications demanding high optical clarity and precision, Plexiglass is the way to go. Understanding these nuances will help you select the right material for your needs, ensuring longevity and performance in your chosen application.

Reference

- Durable and Long-Lasting: Our Transparent Support Clear Polycarbonate Smoked Multiwall Twinwall Plastic Roof Sheet Hollow Greenhouse Panels offer a 10-year guarantee, ensuring that your investment lasts for years to come, providing peace of mind for our valued customer.

- Customizable Options: We cater to diverse needs by offering various thicknesses (3mm-20mm), widths (1220mm and 2100mm), and colors (clear, green, blue, brown, and opal) to match your specific requirements, including customized solutions as requested by the customer.

- Multi-Functional: Our product is suitable for various applications such as greenhouse skylights, carports, awnings, and roofing, allowing you to utilize a single product for multiple purposes and projects, including golf training aids in sports and entertainment.

- Advanced Features: Our polycarbonate sheet boasts impressive features such as anti-aging, thermal insulation, impact resistance, and fire resistance, ensuring a safe and efficient use of the product in various settings.

- Comprehensive After-Sales Support: We provide online technical support, onsite installation, onsite training, and installation instructions to guarantee a seamless and hassle-free experience for our customers, including those who requested specific support and assistance.

-

Product descriptions from the supplier

Warning/DisclaimerThis product has acquired the relevant product qualification(s)/license(s) of certain applicable country/countries.View more

Overview

Video Description

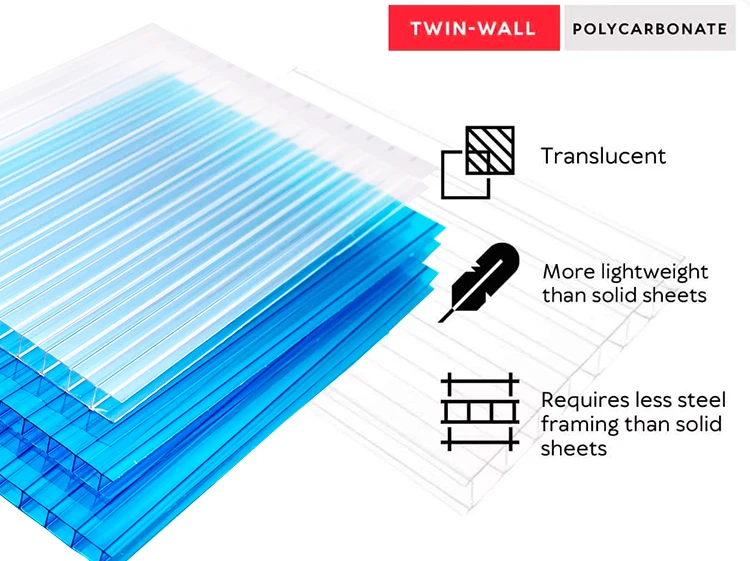

Fire resistant 10mm 16mm twin wall multiwall polycarbonate sheet greenhouse panelMaterial

Virgin PC Warranty

10 years, Grade A quality Thickness

4mm,6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm Width

1220mm 2100mm or can be customized Length

5800mm,12000mm,11800mm,6000mm or can be customized Popular Size

1.22*2.44m,2.1*5.8m,2.1*11.6m,customized Color

Clear, Milk white, Green, Dark blue, Lake Blue, Brown or Customized Features

Light weight: only 1/2 of the glass of the same thickness. High light transmission: up to 88%

Anti-ultraviolet: 50 micron or any UV thickness is added for free.UV protection both sides, or one side.

High impact strength and tensile strength

Fireproof

Thermal insulation

Sound insulation

Application

Bus stop shelter, Building material, Greenhouse, Car garage tents, Advertising boards,Transportation airline, Swimming pool Cover,etc.

Company Type

Manufacturer of polycarbonate sheet Factory Location

Baoding, Hebei province, China Service

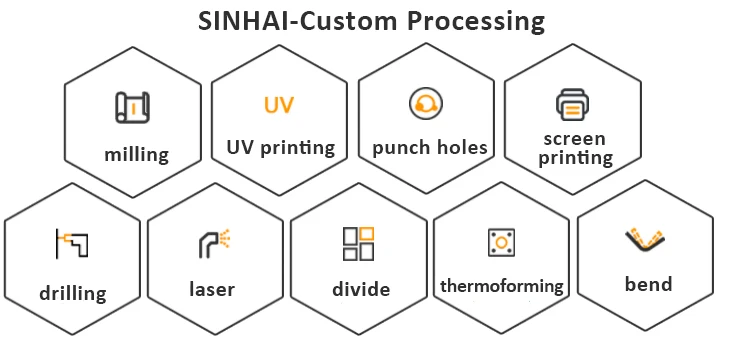

Free sample for testing. Accept OEM/ODM.

24hours instant and comfortable customer service.

Shipping status notification during delivery.

Promotion price

%

Reviews

Clear filtersThere are no reviews yet.