TR Hard Coated Polycarbonate Sheet: Manufacturing Process, Applications, and Benefits

Introduction to TR Hard Coated Polycarbonate Sheets

Polycarbonate sheets are widely used across a variety of industries due to their exceptional strength, durability, and resistance to impact. Among these, TR (thermoformed) hard coated polycarbonate sheets stand out for their superior performance and enhanced properties. These sheets are not only tough and durable but also provide excellent protection against scratches and chemicals, making them ideal for use in demanding environments.

The Manufacturing Process of TR Hard Coated Polycarbonate Sheets

The production of TR hard coated polycarbonate sheets involves several intricate steps that ensure the final product is both robust and reliable. Initially, high-quality polycarbonate granules are melted and extruded into sheets using advanced machinery. After cooling, these sheets undergo a coating process where a scratch-resistant layer is applied. This layer is typically made from UV-stabilized acrylic or silicone, which significantly enhances the sheet’s surface hardness and longevity. Post-coating, the sheets are subjected to rigorous quality checks before being packaged for shipment. Each step in this process is meticulously controlled to maintain consistency and meet stringent industry standards.

Applications Across Various Industries

Due to their unique properties, TR hard coated polycarbonate sheets find extensive applications across multiple sectors. In the automotive industry, these sheets are utilized for manufacturing headlamp covers, window glazing, and interior components due to their light weight and shatter resistance. The construction sector employs these sheets for skylights, canopies, and façade panels, where their ability to withstand harsh weather conditions is particularly valuable. Additionally, these sheets are popular in electronics for protective casings and screens, owing to their excellent optical clarity and resistance to abrasion.

Enhancing Safety and Longevity

One of the most significant advantages of TR hard coated polycarbonate sheets is their contribution to enhancing safety and longevity in products. Their inherent toughness ensures that they can endure extreme impacts without breaking, thereby providing a higher level of protection. Moreover, the scratch-resistant coating maintains the visual appeal and functionality of products over time, reducing the need for frequent replacements. This not only extends the lifespan of the products but also lowers maintenance costs, making them a cost-effective solution for many applications.

Conclusion

In summary, TR hard coated polycarbonate sheets represent a remarkable advancement in material science, offering unparalleled strength, durability, and versatility. From automotive and construction to electronics, these sheets have proven invaluable in numerous industries. By understanding their manufacturing process and recognizing their diverse applications, we can appreciate the critical role they play in enhancing the safety and longevity of products, contributing to more sustainable and efficient solutions.

Reference

Advanced Polycarbonate Sheets for Modern Applications, MaterialsViews, 2022.

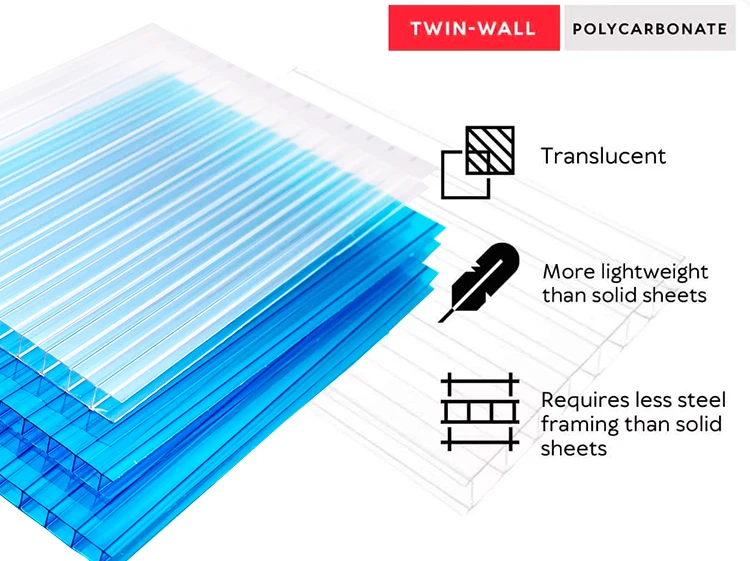

- Durable and Long-Lasting: Our Transparent Support Clear Polycarbonate Smoked Multiwall Twinwall Plastic Roof Sheet Hollow Greenhouse Panels offer a 10-year guarantee, ensuring that your investment lasts for years to come, providing peace of mind for our valued customer.

- Customizable Options: We cater to diverse needs by offering various thicknesses (3mm-20mm), widths (1220mm and 2100mm), and colors (clear, green, blue, brown, and opal) to match your specific requirements, including customized solutions as requested by the customer.

- Multi-Functional: Our product is suitable for various applications such as greenhouse skylights, carports, awnings, and roofing, allowing you to utilize a single product for multiple purposes and projects, including golf training aids in sports and entertainment.

- Advanced Features: Our polycarbonate sheet boasts impressive features such as anti-aging, thermal insulation, impact resistance, and fire resistance, ensuring a safe and efficient use of the product in various settings.

- Comprehensive After-Sales Support: We provide online technical support, onsite installation, onsite training, and installation instructions to guarantee a seamless and hassle-free experience for our customers, including those who requested specific support and assistance.

-

Product descriptions from the supplier

Warning/DisclaimerThis product has acquired the relevant product qualification(s)/license(s) of certain applicable country/countries.View more

Overview

Video Description

Fire resistant 10mm 16mm twin wall multiwall polycarbonate sheet greenhouse panelMaterial

Virgin PC Warranty

10 years, Grade A quality Thickness

4mm,6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm Width

1220mm 2100mm or can be customized Length

5800mm,12000mm,11800mm,6000mm or can be customized Popular Size

1.22*2.44m,2.1*5.8m,2.1*11.6m,customized Color

Clear, Milk white, Green, Dark blue, Lake Blue, Brown or Customized Features

Light weight: only 1/2 of the glass of the same thickness. High light transmission: up to 88%

Anti-ultraviolet: 50 micron or any UV thickness is added for free.UV protection both sides, or one side.

High impact strength and tensile strength

Fireproof

Thermal insulation

Sound insulation

Application

Bus stop shelter, Building material, Greenhouse, Car garage tents, Advertising boards,Transportation airline, Swimming pool Cover,etc.

Company Type

Manufacturer of polycarbonate sheet Factory Location

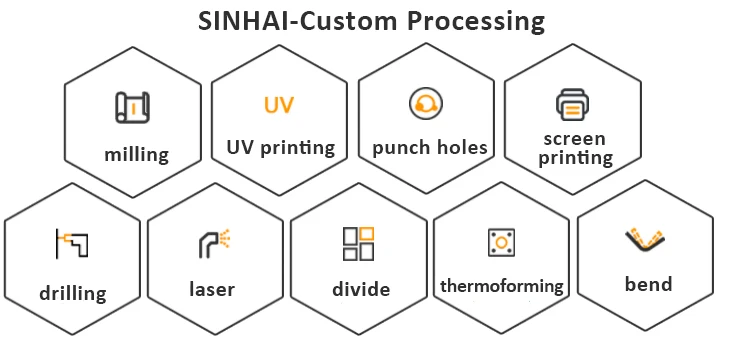

Baoding, Hebei province, China Service

Free sample for testing. Accept OEM/ODM.

24hours instant and comfortable customer service.

Shipping status notification during delivery.

Promotion price

%

Reviews

Clear filtersThere are no reviews yet.