twin wall polycarbonate sheet fixings

Introduction

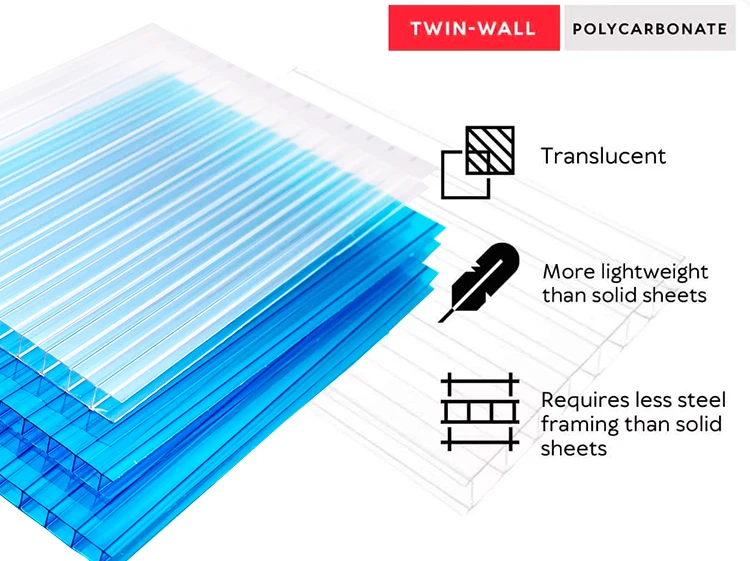

Twin wall polycarbonate sheets are increasingly popular due to their lightweight, durability, and excellent insulating properties. These versatile sheets are widely used in greenhouses, canopies, skylights, and various architectural applications. However, ensuring the longevity and aesthetic appeal of installations requires careful consideration of the right fixing methods. This article will detail the types of fixings suitable for twin wall polycarbonate sheets, how to choose the right fixing method based on project requirements, and provide tips for installation.

Types of Fixings for Twin Wall Polycarbonate Sheets

The choice of fixing method depends on factors such as the application, environmental conditions, and structural design. Common fixing methods include clips, screws, and sealants. Clips are typically made from stainless steel or aluminum and designed to hold the sheets in place while allowing for thermal expansion. Screws should be self-tapping and non-corrosive, often with a washer to distribute pressure evenly. Sealants, like silicone or polyurethane-based products, help prevent water ingress and enhance the overall durability of the installation.

Choosing the Right Fixing Method

Selecting the appropriate fixing method is crucial for both functionality and aesthetics. For instance, in areas prone to high winds, using clips with a strong grip might be necessary to ensure the sheets remain secure. In contrast, in less exposed environments, screws might suffice. It’s also important to consider the ease of installation and maintenance. Clips, for example, allow for easier replacement of damaged sheets without disturbing the entire structure. Always refer to the manufacturer’s guidelines for specific recommendations.

Tips for Installation

To ensure longevity and aesthetic appeal, follow these installation tips:

- Allow for Expansion: Twin wall polycarbonate sheets expand and contract with temperature changes. Ensure your fixings accommodate this movement to avoid cracking.

- Use Appropriate Tools: Use the correct tools for cutting and drilling to prevent damage to the sheets. A fine-toothed saw and a pilot drill bit are recommended.

- Seal Properly: Apply sealant around all edges and at joints to prevent water leakage. Regular inspection and reapplication of sealant are advised.

- Maintain Cleanliness: Keep the sheets clean to maintain transparency and reduce the risk of algae growth. Use mild soap and water for cleaning.

Reference Materials

For further reading on the topic, you may find the following resources helpful:

Polycarbonate Sheets: An Overview of Applications and Installation Tips

Engineering Toolbox: Properties of Polycarbonate

- Durable and Long-Lasting: Our Transparent Support Clear Polycarbonate Smoked Multiwall Twinwall Plastic Roof Sheet Hollow Greenhouse Panels offer a 10-year guarantee, ensuring that your investment lasts for years to come, providing peace of mind for our valued customer.

- Customizable Options: We cater to diverse needs by offering various thicknesses (3mm-20mm), widths (1220mm and 2100mm), and colors (clear, green, blue, brown, and opal) to match your specific requirements, including customized solutions as requested by the customer.

- Multi-Functional: Our product is suitable for various applications such as greenhouse skylights, carports, awnings, and roofing, allowing you to utilize a single product for multiple purposes and projects, including golf training aids in sports and entertainment.

- Advanced Features: Our polycarbonate sheet boasts impressive features such as anti-aging, thermal insulation, impact resistance, and fire resistance, ensuring a safe and efficient use of the product in various settings.

- Comprehensive After-Sales Support: We provide online technical support, onsite installation, onsite training, and installation instructions to guarantee a seamless and hassle-free experience for our customers, including those who requested specific support and assistance.

-

Product descriptions from the supplier

Warning/DisclaimerThis product has acquired the relevant product qualification(s)/license(s) of certain applicable country/countries.View more

Overview

Video Description

Fire resistant 10mm 16mm twin wall multiwall polycarbonate sheet greenhouse panelMaterial

Virgin PC Warranty

10 years, Grade A quality Thickness

4mm,6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm Width

1220mm 2100mm or can be customized Length

5800mm,12000mm,11800mm,6000mm or can be customized Popular Size

1.22*2.44m,2.1*5.8m,2.1*11.6m,customized Color

Clear, Milk white, Green, Dark blue, Lake Blue, Brown or Customized Features

Light weight: only 1/2 of the glass of the same thickness. High light transmission: up to 88%

Anti-ultraviolet: 50 micron or any UV thickness is added for free.UV protection both sides, or one side.

High impact strength and tensile strength

Fireproof

Thermal insulation

Sound insulation

Application

Bus stop shelter, Building material, Greenhouse, Car garage tents, Advertising boards,Transportation airline, Swimming pool Cover,etc.

Company Type

Manufacturer of polycarbonate sheet Factory Location

Baoding, Hebei province, China Service

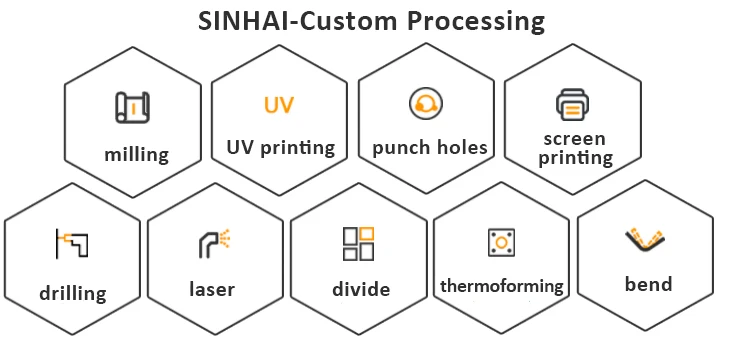

Free sample for testing. Accept OEM/ODM.

24hours instant and comfortable customer service.

Shipping status notification during delivery.

Promotion price

%

Reviews

Clear filtersThere are no reviews yet.